Capturing and storing CO2 for climate protection

The capture and storage of the most common greenhouse gas CO2 in the atmosphere is an important component of any climate strategy. Increasing the pricing and taxation of CO2 will boost CO2 capture technology over the coming decade.

Text: Daniel Fauser

Climate change will once again be the subject of public discussion next November as part of the 26th Conference on Climate Change of the United Nations (COP26) in Glasgow. The record-breaking number of extreme weather events in the summer of 2021, with floods, droughts, forest fires and hurricanes, has provided a taste of the future negative effects of global warming.

The main driver of this global warming is the rapidly increasing concentration of carbon dioxide (CO2) in the atmosphere. CO2 accounts for 74.4 percent of global greenhouse gases (measured by global warming potential, which is significantly higher for methane, for example). If the negative effects of global warming are to be contained, reducing CO2 emissions is an absolute necessity.

Carbon capture and storage is technologically practical

A large part of the CO2 reduction path to reach the Paris climate goal can be achieved with renewable energies, energy efficiency gains and increasing electrification. But only one part of it. The International Renewable Energy Agency (IRENA) estimates that around 6 to 10 percent of CO2 is emitted in areas where emissions are very difficult or even impossible to avoid – for example in cement and steel production. Carbon capture, utilisation and storage (CCUS) is seen by experts as a technologically effective method of removing CO2 in a wide range of sectors.

Use of this technology is possible and already in practice

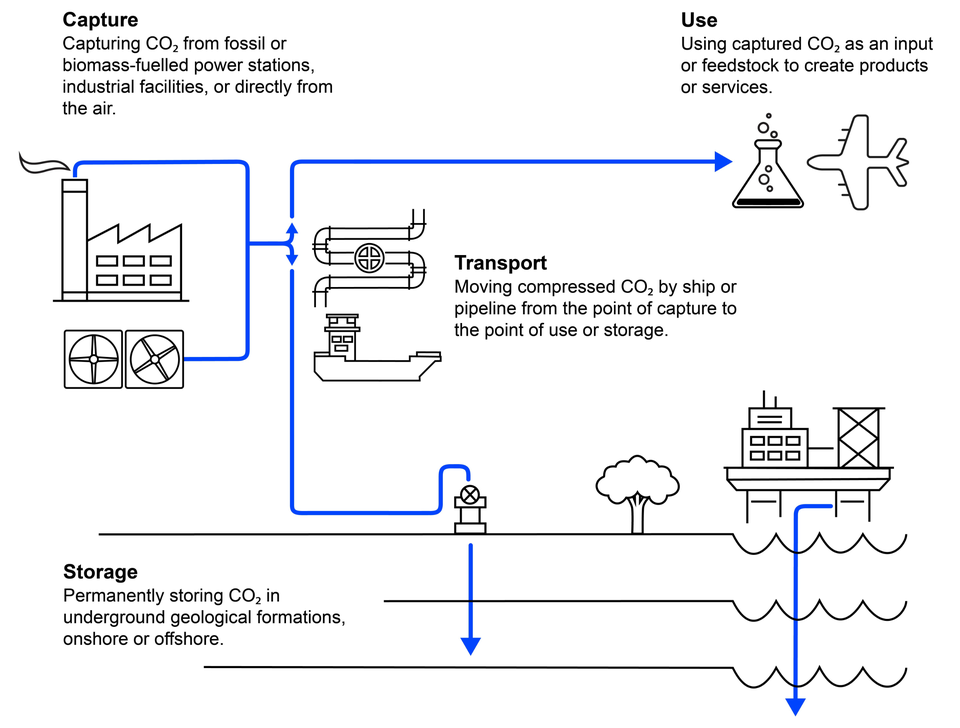

CCUS involves the capture (or filtration) of CO2 from a number of sources (including air) and transport by pipeline or ship for utilisation or permanent storage (see diagram). The technology is already being used in power generation and in industrial plants that use fossil fuels or biomass, such as those that produce hydrogen. Captured CO2 can be used on site or transported in compressed form. For instance, it can be used to produce synthetic aircraft fuel or permanently stored in geological formations such as exhausted oil and gas deposits.

The CCUS process

Costs of CCUS are still high

The first CCUS plants have been in operation since the 1980s, but only in very selected applications where the CO2 concentration is high, such as ammonia production or natural gas processing. The first plant was built in the Texan region of Val Verde.

Generally, the higher the CO2 concentration is, the lower the cost of capturing one tonne of CO2 (see chart below). This rule of thumb is also the reason why capturing CO2 directly from the air is the most cost-intensive CCUS variant. In the exhaust gases of a coal-fired power plant, for example, the CO2 concentration is much higher than in the air, where it is only 0.04 percent by volume. In addition, CO2 should preferably be captured where it is also recycled or permanently stored. Otherwise, the average cost of capturing one ton of CO2 of about USD 80/tonne has to be added to the USD 10/tonne for transport and USD 30/tonne for storage. Today, the cost of permanently storing one tonne of CO2 in the USA is therefore around USD 120/tonne.

Only a high CO2 price provides an incentive to use CCUS

The economic attractiveness of CCUS is inseparably linked to CO2 pricing and taxation. The arithmetic is as simple as it is true: in the future, CO2 prices will have to rise to well over USD 100/tonne. As long as it is cheaper to emit a tonne of CO2 into the air than to store it, there is no economic incentive to build CCUS plants without state subsidies. It is likely that the cost of CCUS will decrease somewhat over the next few years due to advances in technology or scaling effects. The growing use of CCUS suggests that the technology enjoys broad political support in both the EU and the USA, as CO2 emissions from certain sectors cannot be prevented but only neutralised.

CCUS as part of our global equity strategy

In recent years, it has been observed that companies in the «traditional» energy and raw materials sector in particular are moving towards CCUS. Examples are integrated oil companies such as Keyera (Canada) or Calix (Australia). However, there are also companies specialising purely in CCUS, such as Aker Carbon Capture, Jericho Energy Ventures and HTC Purenergy.

Zürcher Kantonalbank monitors the technological and political developments in CCUS and evaluates opportunities at individual companies with its fundamental, ESG-integrated research approach. We may implement our findings as part of our global, sustainable equity strategy.

Cost of CO2 capture without transport and storage

Source: IEA analysis based on own estimates and

- GCCSI (2017), Global costs of carbon capture and storage, 2017 update, Global costs of carbon capture and storage, 2017 update - Google Scholar

- IEAGHG (2014), CO2 capture at coal based power and hydrogen plants, 2014-03 CO2 Capture at Coal-Based Power and Hydrogen Plants (ieaghg.org)

- Keith et al. (2018), A Process for Capturing CO2 from the Atmosphere, A Process for Capturing CO2 from the Atmosphere: Joule (cell.com)

- NETL (2014), Cost of capturing CO2 from Industrial sources, Energy Analysis | netl.doe.gov

- Rubin, E. S., Davison, J. E. and Herzog, H. J (2015), The cost of CO2 capture and storage The cost of CO2 capture and storage | Request PDF (researchgate.net)